For all sectors in which quality is a top priority

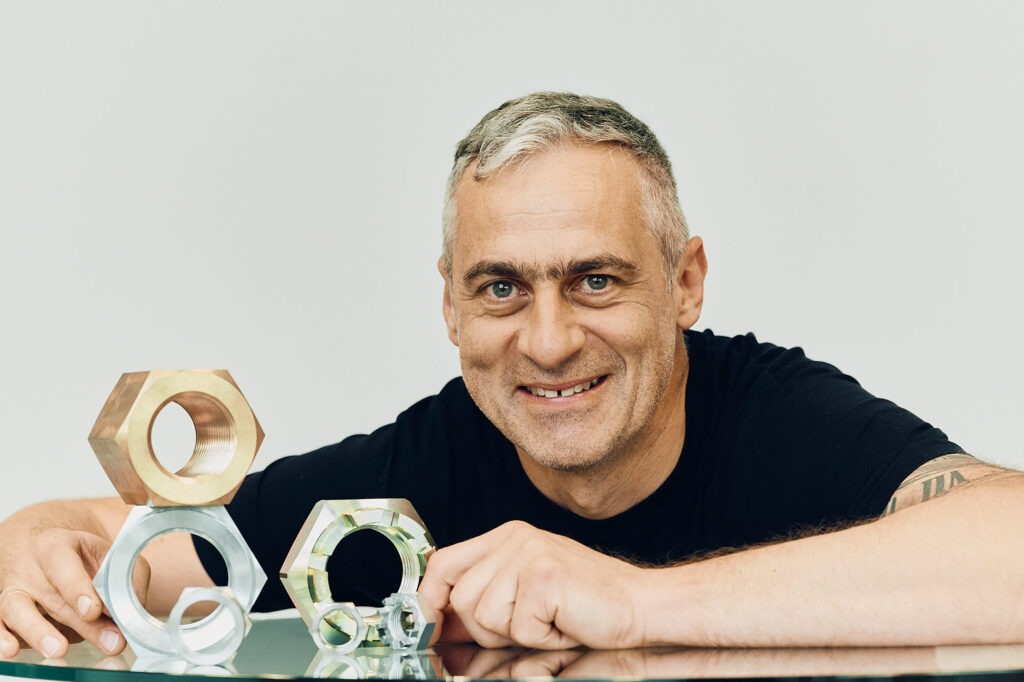

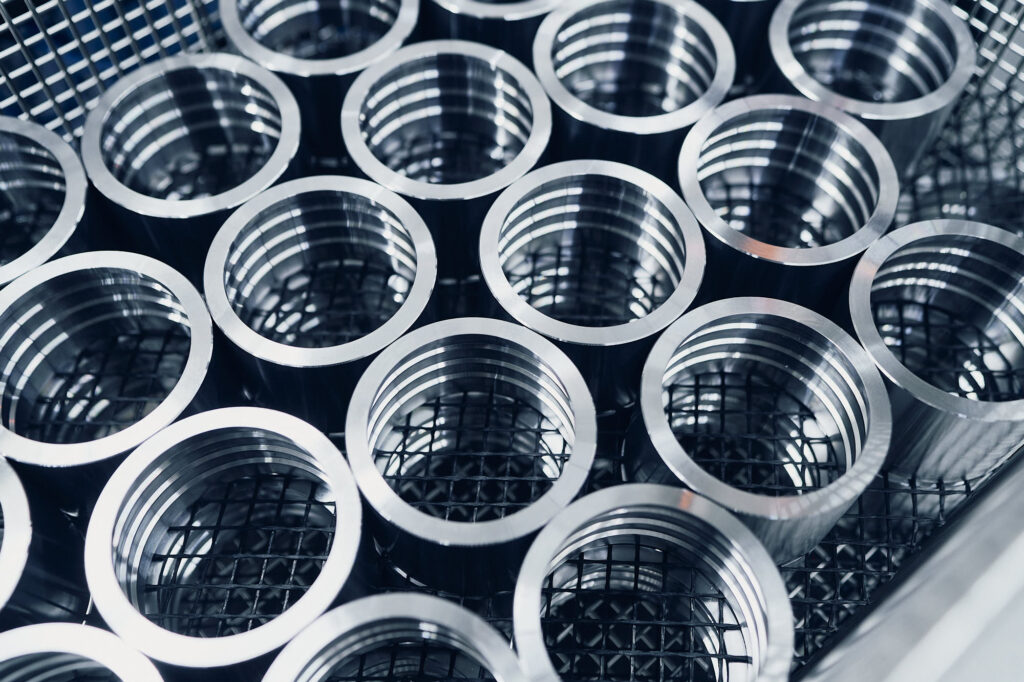

Hexagon nuts, castellated nuts, round nuts, cap nuts, slotted nuts and special nuts according to drawing. From prototypes to small and medium quantities and in all common materials, special materials on request.

Our plus:

SW 19 to SW 95 mm

M 12 to M 64

Metric, fine, UNC, UNF, WW, pipe thread

Also partly in left version

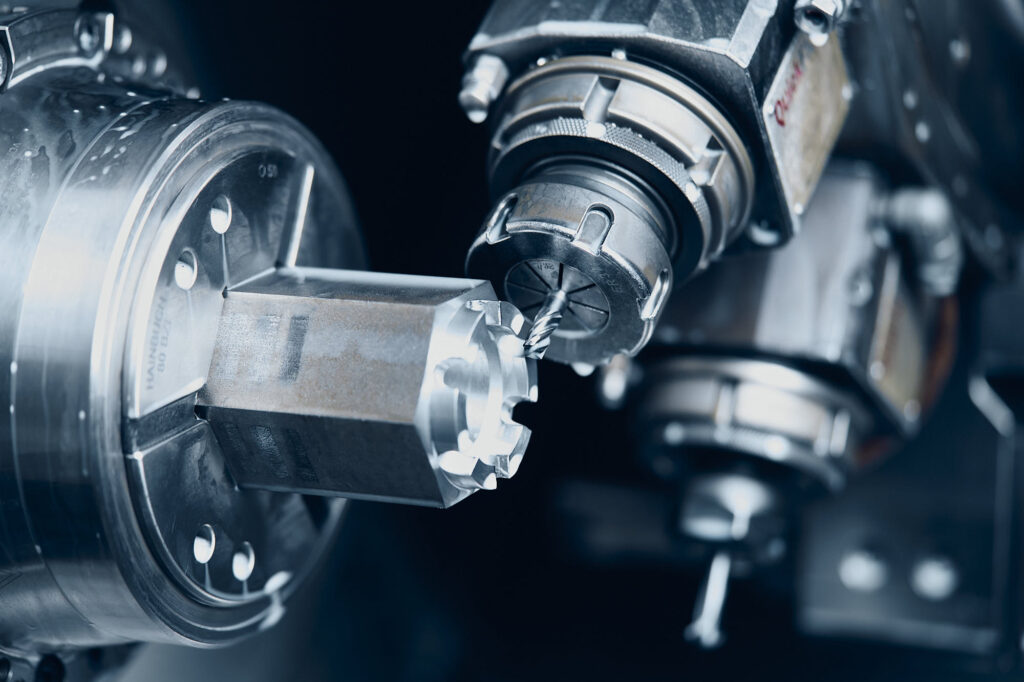

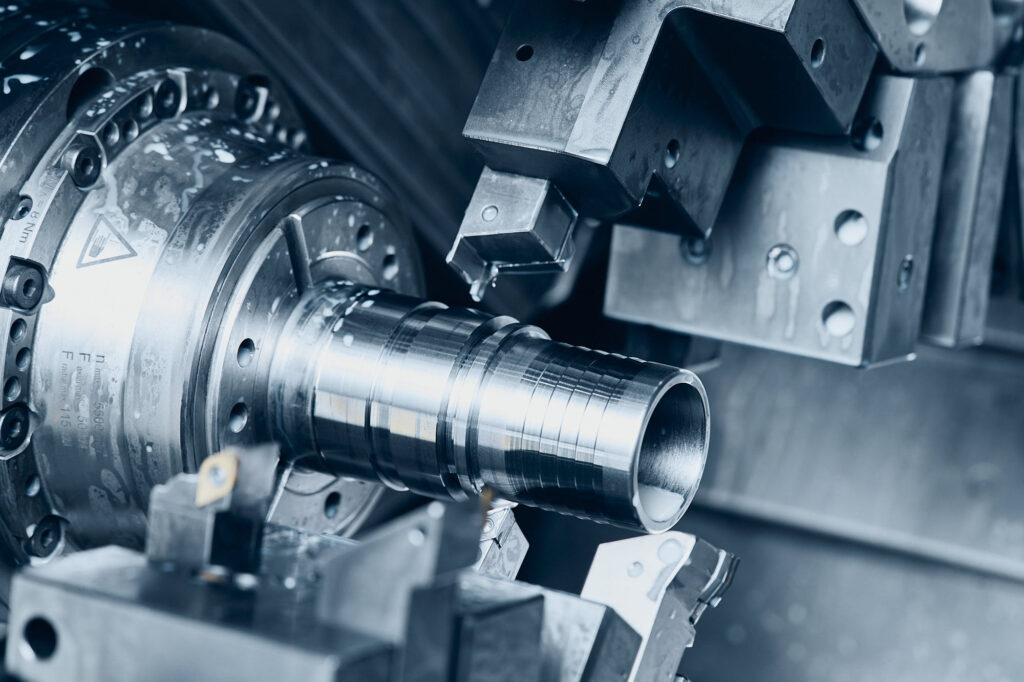

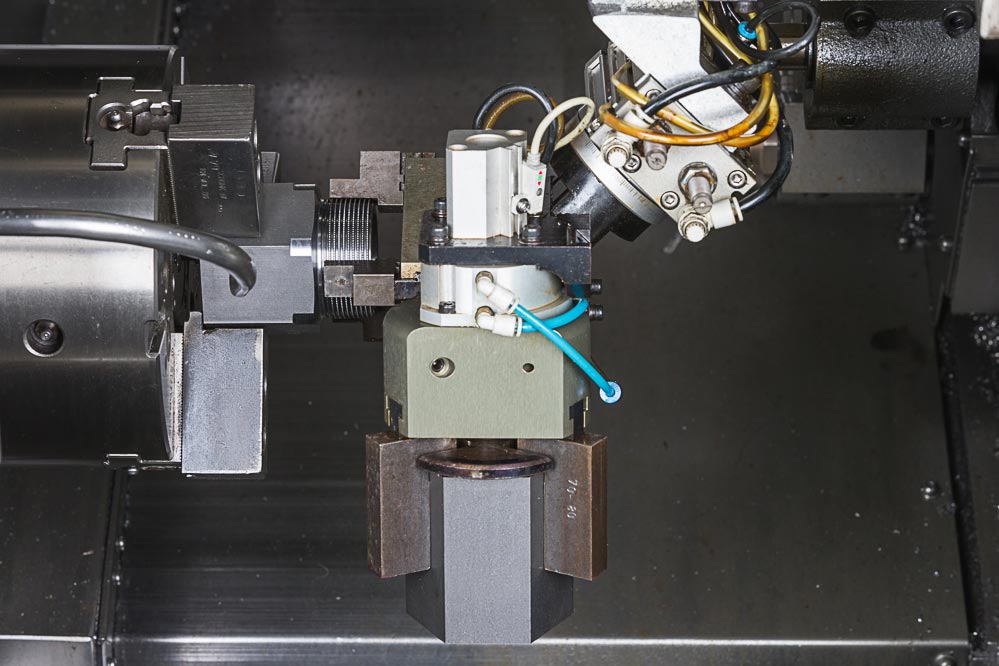

Turned/milled parts completely manufactured on CNC turning/milling machining centers.

Chuck turned parts and contract machining of supplied blanks.

All these pictures are examples of production

Ø 16 to Ø 90 mm from bar

Ø 40 to Ø 150 mm

as chuck turned parts

Length max. 250 mm

Small & medium

quantities, prototypes

Mixing unit For environmental technology

Completely manufactured on a 5-axis CNC turning/milling machining center with milling, face and cross threads and through-hole drilling

Screw-in connector

For sensor technology

Completely manufactured on a CNC turning/milling machine. Passage Ø 70mm, 6 kt-SW 55 mm milled with simultaneous front and rear machining

Adapter For fluid technology

Completely manufactured on a CNC turning/milling machine | Ø 50mm aperture | Surface Ra 0,8 | Tolerances IT 7

Flange For mechanical engineering

Manufactured on a CNC lathe in a chuck Ø 120 mm in two clamping positions, with face and threaded holes | Surface Rz 16 | Tolerances IT 7

For MAXIMUM quality. We make sure that everything runs as it should.

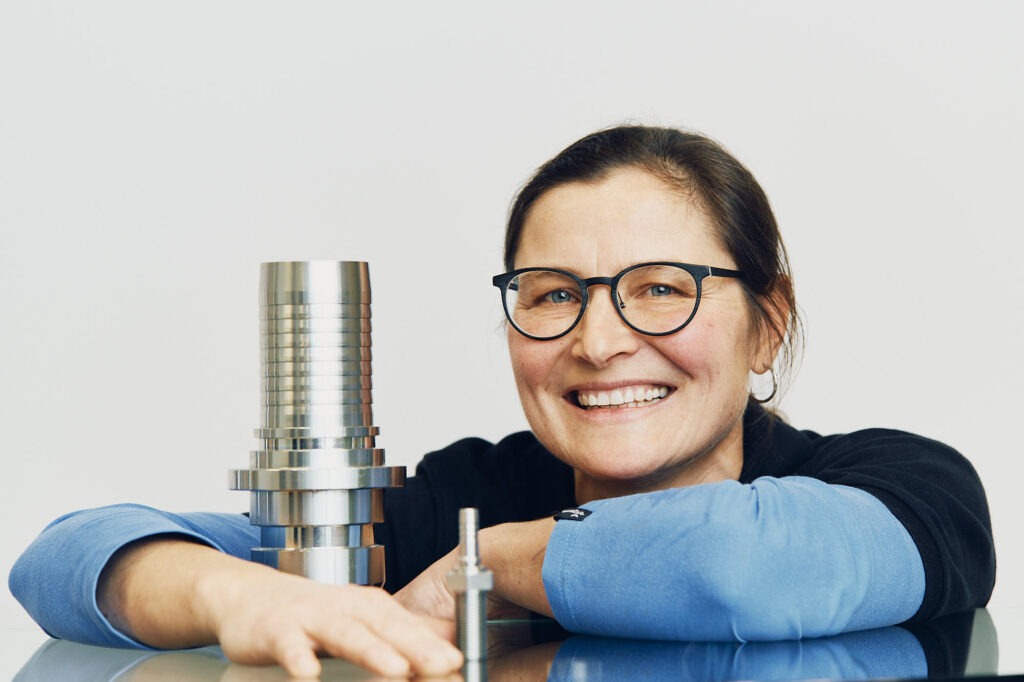

We manufacture hose nipples for fluid technology/hydraulics in various thread sizes and dimensions. The materials available are stainless steel and steel, bright or galvanized.

from Ø 16 to Ø 90 mm from bar

from Ø 40 to Ø 150 mm

as chuck turned parts

Length max. 250 mm

Small & medium quantities, prototypes

e.g. for automotive, mechanical engineering, electrical and vibration technology etc.

Ø 40 to Ø 150 mm

Small & medium

quantities, prototypes

Post-processing of blanks

Contract manufacturing